Category

New Product Non Standard Automation Aoi Equipment Industrial Parts Optical Sorting Vision Inspection Machine

Overview Our intelligent equipment products include visual inspection machine, laser detection machine, high-speed count

Overview

Our intelligent equipment products include visual inspection machine, laser detection machine, high-speed counting machine, coordinate measuring instrument, non-destructive inspection machine, robots, precision optical lens and automatic production line. At the same time, it also acts as an agent for foreign high-quality products, including 3D cameras, laser measurements, line-scan cameras, online detection software, artificial intelligence software, non-destructive testing instruments and other optical devices.

The optical sorting machine adopts high-resolution CCD industrial lens, combined with OPENEX's self-developed 360° system and accurate image recognition software. They can achieve the most inspection requirements with the least number of cameras, saving cost for customers to the greatest extent and expanding production capacity.

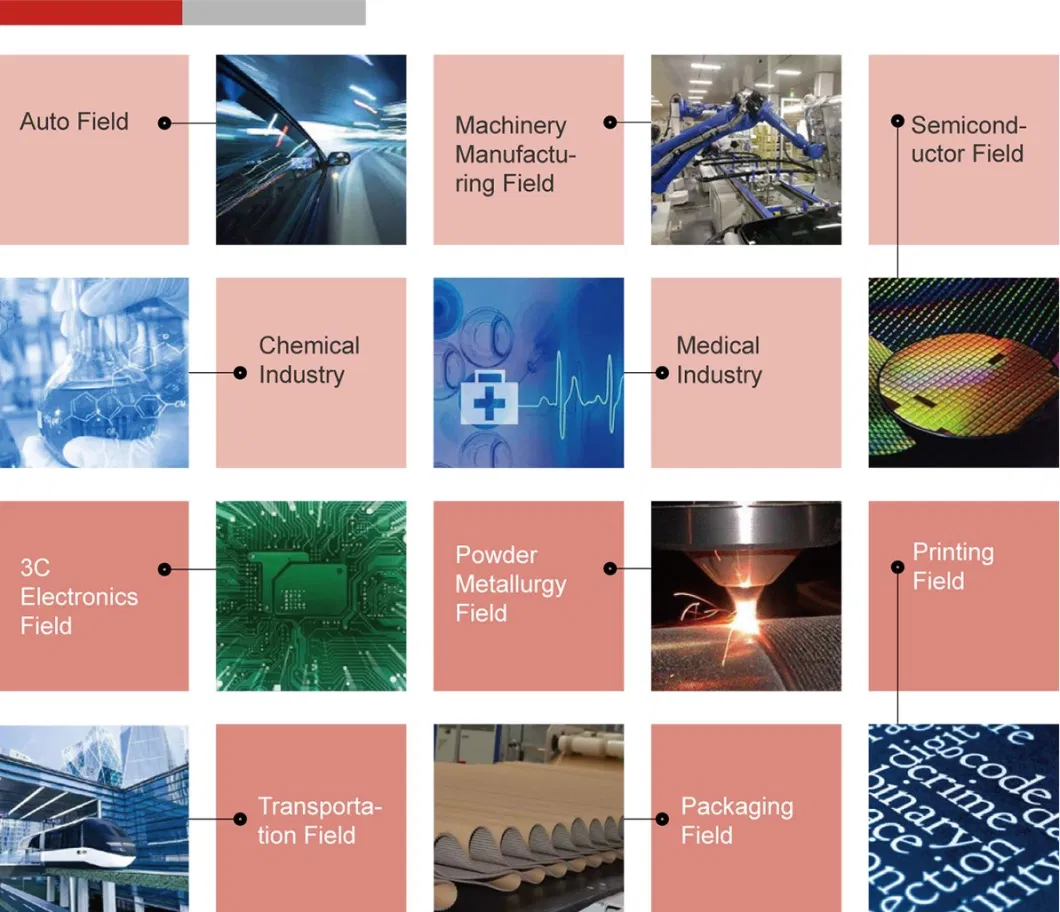

Openex inspection machine is suitable for parts and defects inspection in metal, magnet, electronic, plastic, rubber and other fields, covering many industries such as automobile, electronics, medicine, manufacturing, etc. It has become a wise choice for quality control in various industries.

AI solutions can detect tiny flaws that traditional algorithms cannot solve.

AI solutions can adapt to variable interference factors and poor lighting conditions, making them compatible with more product types.

When introducing new products, there is no need to rewrite the core algorithm and only need to set a few parameters to meet the requirements.

The software allows users to complete the training and deployment of algorithm models of new artifacts by themselves.

Over the past decade, Openex has served more than 1,000 customers and generated billions of yuan in revenue. We have a full pre-sales and after-sales team, engineering operation and maintenance team, which can provide customers with the most professional equipment and services from R&D to implementation.

Inspection CapabilitiesThrough visual imaging, laser scanning, three-dimensional reconstruction, non-destructive testing and other means, with independent research and development of software and algorithms, material 100% size measurement and defect detection, so as to improve customer product quality and production control capabilities, and achieve leap-forward growth in customer competitiveness.Contact Us

Basic Info.

| Type | Customizable |

| Transport Package | Customized |

| Specification | Customized |

| Trademark | OPENEX |

| Origin | China |

| HS Code | 9031800000 |

Product Description

Our intelligent equipment products include visual inspection machine, laser detection machine, high-speed counting machine, coordinate measuring instrument, non-destructive inspection machine, robots, precision optical lens and automatic production line. At the same time, it also acts as an agent for foreign high-quality products, including 3D cameras, laser measurements, line-scan cameras, online detection software, artificial intelligence software, non-destructive testing instruments and other optical devices.

The optical sorting machine adopts high-resolution CCD industrial lens, combined with OPENEX's self-developed 360° system and accurate image recognition software. They can achieve the most inspection requirements with the least number of cameras, saving cost for customers to the greatest extent and expanding production capacity.

Openex inspection machine is suitable for parts and defects inspection in metal, magnet, electronic, plastic, rubber and other fields, covering many industries such as automobile, electronics, medicine, manufacturing, etc. It has become a wise choice for quality control in various industries.

Openex's optical inspection machine is suitable for defects inspection of mechanical parts, like metal, magnet, electronic, plastic, rubber and other components, covering many industries such as automobile, electronics, medicine, manufacturing, etc.

AI solutions can detect tiny flaws that traditional algorithms cannot solve.

AI solutions can adapt to variable interference factors and poor lighting conditions, making them compatible with more product types.

When introducing new products, there is no need to rewrite the core algorithm and only need to set a few parameters to meet the requirements.

The software allows users to complete the training and deployment of algorithm models of new artifacts by themselves.

Over the past decade, Openex has served more than 1,000 customers and generated billions of yuan in revenue. We have a full pre-sales and after-sales team, engineering operation and maintenance team, which can provide customers with the most professional equipment and services from R&D to implementation.

Inspection CapabilitiesThrough visual imaging, laser scanning, three-dimensional reconstruction, non-destructive testing and other means, with independent research and development of software and algorithms, material 100% size measurement and defect detection, so as to improve customer product quality and production control capabilities, and achieve leap-forward growth in customer competitiveness.Contact Us